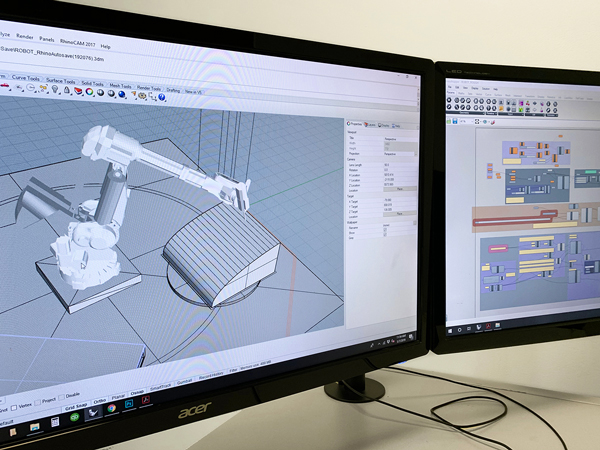

Design Development

Timbur’s staff is extremely proficient in a number of 3d modeling, CAD and CAM software platforms. From parametric modeling and laser scanned sight surveys to detailed shop drawings and full-scale architectural mock-ups Timbur knows how to use computers to make machines work for you.

7-Axis Robotic Machining

Timbur’s ABB IRB 6400R industrial robot and its expansive 3 meter work envelope enables them to machine large scale complex forms that are often not achievable with traditional 3 and 5-axis machining technology.

3-Axis CNC Machining

Timbur’s large envelope 6’x12’ flat bed CNC router enables them to machine sheet goods that come in large unconventional sizes. Timbur has put it to great use for their clients machining projects that range from custom furniture to full scale commercial building facades.

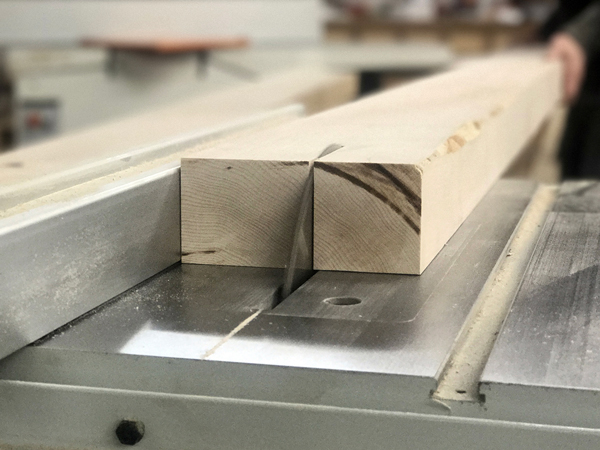

Millwork/Fabrication

In addition to their CNC capabilities Timbur maintains a traditional millwork shop, well stocked with woodworking machinery and staffed with experienced millworkers, that offers custom woodwork, assembly and finishing.

Delivery/Installation/Sitework

Whether it is a matter of detailed installation instructions, close coordination with a General Contractor or a crew of on-site tradesmen Timbur has the resources available to get your project finished. Let them draw on their network of experienced professionals for you.

Architecture Background

Founded by Ezra Ardolino (M.Arch.) who has taught architecture at both Pratt Institute and Cornell University, Timbur has a unique ability to connect with Architecture and Design professionals understanding their needs, limitations and desires.